Towards the next

fuel cell

generation

Towards the Next

Generation Fuel Cells

what we do

Providing technical solutions

We create novel products & services with unique technical and economical benefits as market enabler for a clean and sustainable energy conversion and storage.

With a strong focus on market needs, we develop and produce functionalized materials and components for PEM fuel cells and electrolyzers and provide efficient production processes thereof.

Our vision is a mature fuel cell technology linked to an ecologically worthwhile hydrogen production and infrastructure as inevitable part of tomorrow’s energy economy.

solution

What makes us unique

The bipolar plate (as repeating unit) is a key component for high technical efficiency, longevity and cost effectiveness of fuel cell stacks. An automotive fuel cell system of 120 kW contains around 350 bipolar plate assemblies with a total surface area of 50 m2.

Surface area is the key – bulk is ballast!

Therefore, ultra-thin materials in combination with innovative manufacturing processes reveal a smart solution for the volume production of fuel cells.

We provide materials and coatings for thin and lightweight metal bipolar plates in order to ensure high power density as well as longterm stability of fuel cells.

material

Functionalized carbon-based materials for superior conductivity and protection

process

Highly scalable non-vacuum production processes

uniqueness

Competitive benefits due to unique features in the markt

cost

High economies of scale

coating technology that meets the industrial needs

Technology

Scale-up & growth

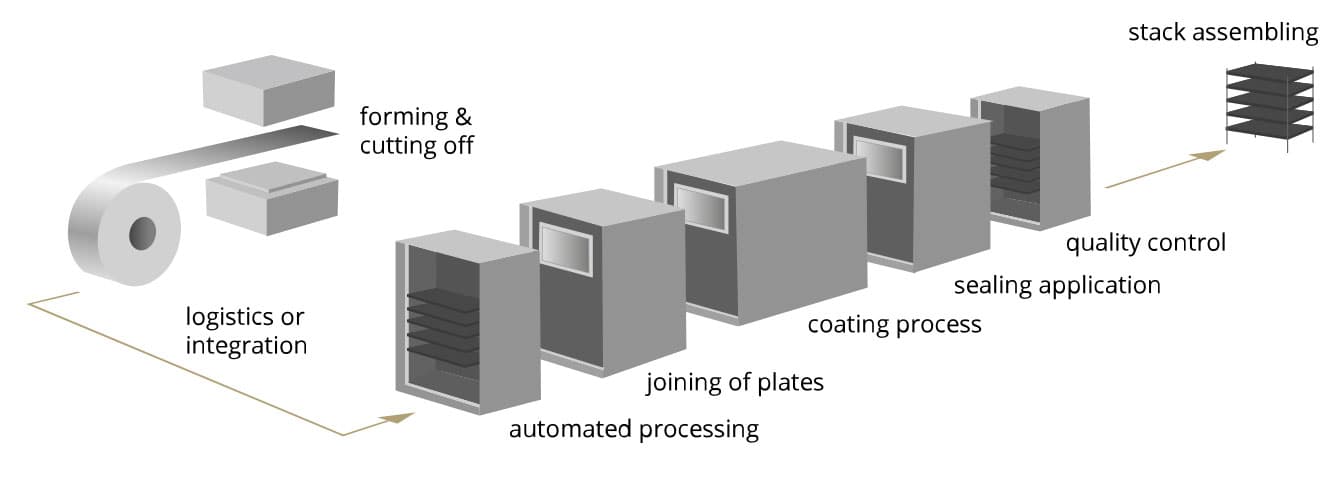

Post-coating

start small – we offer a lean and efficient coating service for customized bipolar plates

think big – we are paving the way to an one-stop solution for the entire bipolar plate as a complete product

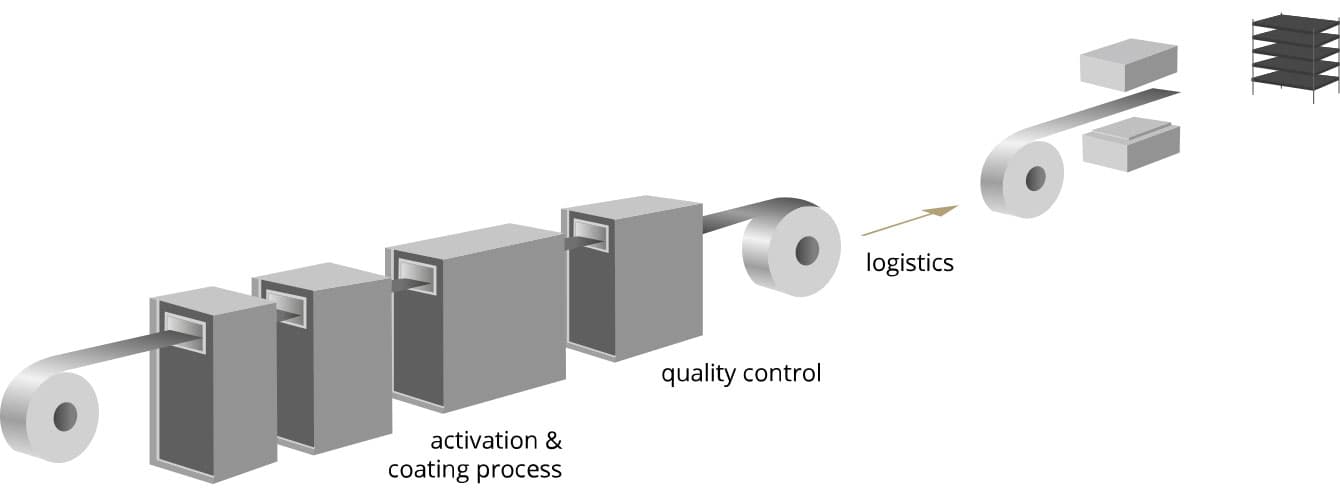

Pre-coating

- we offer a proprietary roll-to-roll coating service for the subsequent bipolar plate production

- we provide various coated materials and types, such as stainless steel and titanium

- let our products speak for themselves – contact us for specs and test coils

together, we create.

company

passion led us here

unraveling the challenges

of metallic bipolar plates

unraveling the challenges of metallic bipolar plates

milestones

- relocation to a new plant to

scale production - strategic collaboration with

industrial partner on mass

production of bipolar plates - 2nd stage investment

- developing novel production

processes for metal plates in

federal project "COBIP" - cooperation agreements with

leading fuel cell companies - FCK CRN

- deployment of enhanced

material synthesis - rise in production capacity

- supplying material & coating

service for on-road test fleet

- federal project "PRECOIL" marks beginning of pre-coated materials

- development of roll-to-roll coating

line for ultra-thin metal foils - precors offers both pre-coated

coils & post-coated bipolar plates

- precors gmbh founded

- 1st stage investment

- installation of coating

line for bipolar plates

- lightbulb moment at

research center Juelich - federal project "EXIST"

leveraged decisive R&D - "f-cell" award for innovation

career

be part of our team!

We are constantly looking for people to lead our work delivering cutting-edge products with the mindset to change current paradigms…